Good woodturning requires skill, a lathe, and high-quality cutting tools. Whether you choose to start with spindle turning or faceplate turning, these are the necessary components.

One of the most rewarding woodworking skills is woodturning on a lathe. It requires significant patience, precision, and practice. However, with the right approach and an understanding that challenges may arise, all you need to start is a good set of woodturning tools.

Due to the abundance of choices available and the extensive technical terminology to comprehend, it can often be more difficult to find the most suitable woodworking tools for your requirements compared to the actual project you wish to accomplish.

You don’t need to worry because the research on essential woodturning tools has already been completed for you. You will find a compilation of the best woodturning tools for beginners here. Additionally, if you aspire to enhance your skills further, it is advised to refer to our guide on the top online woodworking courses.

Wood lathe tools

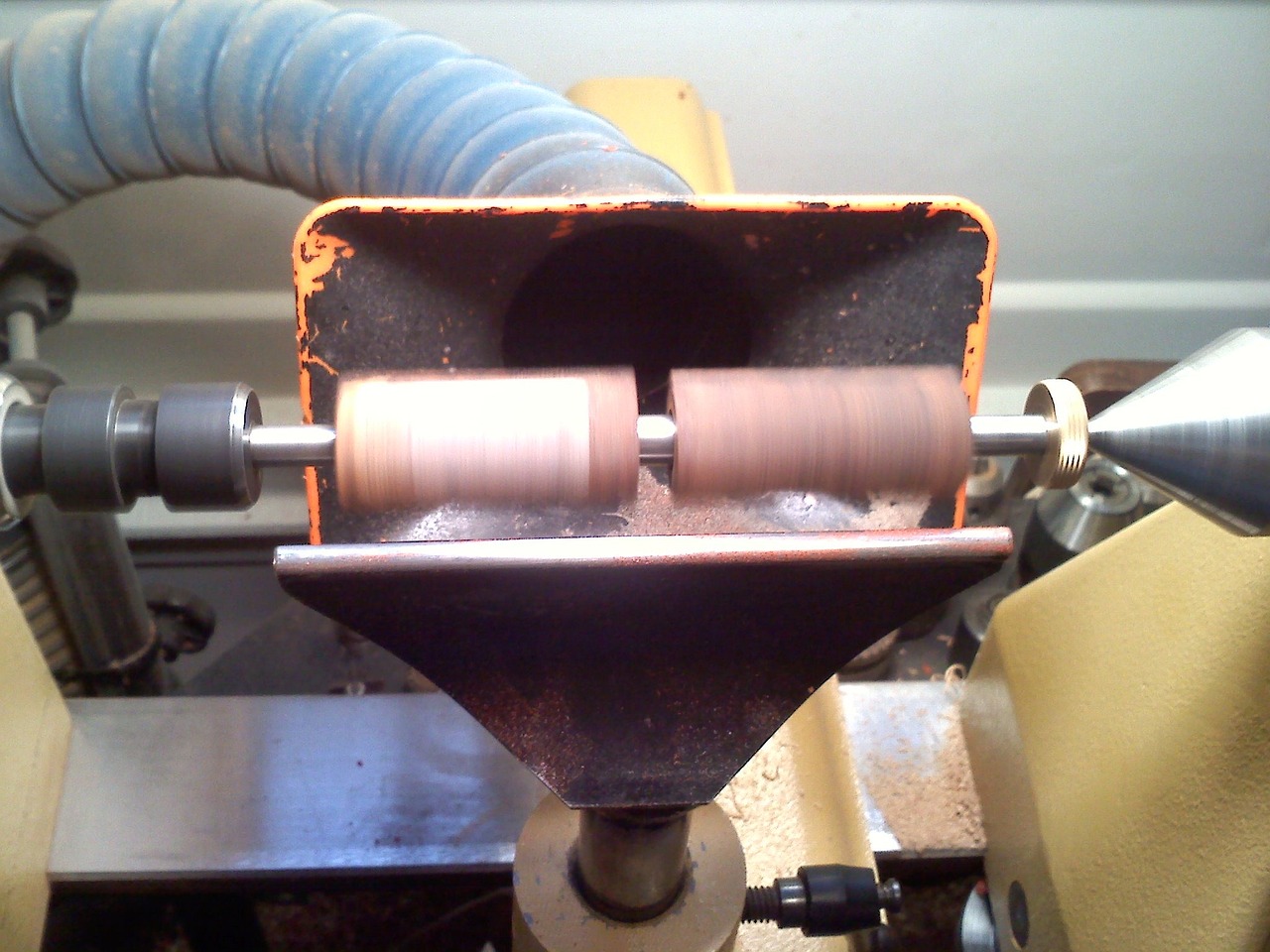

In order to learn the craft of woodturning, the initial tool you will require is a wood lathe. Wood lathes are utilized to produce cylindrical shapes from wood and are equipped with fixtures and devices for securing the woodturner’s projects. After attaching the project to the wood lathe, woodturning tools such as gouges and scrapers are utilized to achieve the desired appearance.

The cost of lathe tools varies depending on your preferences, with smaller manual options for beginners priced significantly lower than larger electric wood lathes used by experienced turners. Additionally, when purchasing your first lathe, it is common for basic woodturning tools necessary for operation to be included, such as:

Faceplates are circular metal plates that hold the wood you are using on a lathe. Before starting to turn, you secure your piece for faceplate work by clamping it down. Additionally, for larger pieces, you have the option to attach them to spindle-mounted faceplates using bolts or screws.

Drive centers make use of the wood lathe’s power to rotate project pieces. They are inserted into the headstock spindle and effectively fasten wood to the lathe, gripping the end so that it can be turned.

An adjustable tool rest is typically found on wood lathes, which serves the purpose of making it easier and consistent to position your woodturning tools. The tool rest is positioned slightly below the centerline of the stock, and it should be placed as close as possible to the cutting edge of your work. This helps minimize the chances of a woodturning tool getting caught and thrown.

Wrenches are beneficial tools for woodturners, aiding in the quick release of faceplates and tool rests, as well as allowing for adjustments to the height of the tool rest. Additionally, they enable the secure attachment of wood to the wood lathe in a simple and efficient manner, providing a sense of confidence during use.

Basic spindle turning tools

There are two categories of woodturning: spindle and faceplate. The tools utilized for spindle turning are distinct from those used for faceplate turning. Spindle turning specifically involves working on projects where the wood is placed between the centers at both ends. Examples of spindle turning projects include chair and table legs, wooden spoons, and pens.

1. Roughing gouge

The tool commonly known as a roughing gouge is utilized in both spindle and faceplate turning activities. As its name implies, the roughing gouge is typically the initial tool employed by woodturners in any given project. Due to its tendency to encounter debris and its capability to efficiently eliminate larger amounts of wood in a single pass, roughing gouges must possess durability and ease of maintenance.

Selecting high-quality gouges, such as these Yellowhammer roughing gouges, is crucial for maintaining an efficiently functioning workshop and managing expenses effectively, which is particularly important when aiming to generate income with your lathe.

2. Spindle gouge

The spindle gouge is specifically made for delicate and accurate turning tasks, presenting a greater level of difficulty compared to the bowl gouge, which is used for faceplate turning.

Spindle gouges in this Hurricane Turning Tools set possess a sharp angle, contributing to their difficulty to control, particularly when the wood lathe is operating at high speeds. This heightened bevel angle also presents a challenge in terms of sharpening the spindle gouges, thus it is essential to refresh one’s knowledge on how to sharpen woodturning chisels.

Once you have created basic shapes using the spindle roughing gouge, the spindle gouge is utilized to incorporate trendy detailing to your work.

Spindle gouges, which have a shallow flute design, can be manipulated by woodturners to create fine details such as beads and coves. These gouges have a fingernail grind, indicating that their edges are ground back to provide better clearance during projects. Generally, beginners in woodturning find a 1/2-inch spindle gouge sufficient for their needs.

3. Skew chisel

Skew chisels, which are essential tools in any spindle turning toolbox, can be difficult to master.

Skew chisels are useful tools for transitioning between shapes within a single piece and for refining wood surfaces and creating intricate v-grooves, thereby enhancing the visual appeal of a project. Mastering the use of skew chisels can greatly differentiate your products on platforms like Etsy, increasing their prominence among other offerings.

If you’re using a skew chisel for the first time, it’s generally advisable to opt for pine instead of the hornbeam handles used in these Narex skew chisels. Pine is a softer and more forgiving material, making it perfect for beginners to practice working with this tool on a lathe.

Skew chisels are worth the effort to learn because they can enhance your skills in wood turning, although it can be challenging to master them.

When selecting woodturning chisels suitable for beginners, it is recommended to choose a 1/2-inch skew chisel with a sharp cutting edge for your toolbox. This tool assists in achieving a flat and polished surface by smoothly removing cuts of wood with its rounded tops and bottom edges, making it an excellent choice for refining your projects.

4. Parting tool

Parting tools are utilized for creating deep channels within the depth of a spindle project and are also well-suited for delineating transitions between shapes. This quality makes them particularly suitable for adding intricate details to chair, table, and bedpost legs.

Be vigilant for parting tools that have a diamond-shaped head, as this decreases the chances of encountering skips and jumps on uneven corners. Parting tools are commonly utilized along with turning calipers, which enable you to measure the diameter of the object you are crafting.

5. Scraping or finishing tool

Not all finishing tools are identical; however, scrapers and finishing tools play essential roles in attaining a furniture-quality finish. Their primary function is to eliminate dents, dings, and other imperfections during the final stages of the project.

The Easy Wood Tools finisher, for example, includes carbide tips and is more versatile compared to conventional scrapers. Regardless of the option you select, becoming proficient in using a scraper is necessary for those seeking to advance beyond the initial phases of woodturning.

6. Scraper

Scrapers are used by wood and bowl turners to smooth out cutting and tool marks that are created by other tools like a bowl gouge. These woodturning tools have a burr instead of a blade and are available in various grinds.

A round nose scraper is designed to remove marks that occur inside hollowed-out objects, whereas square nose scrapers are intended for use on the outside of projects. It is advisable for beginner woodturners to acquire a 1-inch scraper in order to achieve consistent and versatile outcomes.

7. Bowl gouge

Bowl gouges, exclusively used for bowl turning, are available in two common shapes which are U and V, and they are responsible for shaping both the interior and exterior of bowls.

U-shaped bowl gouges can provide a smooth cutting action when shaping the underside of a surface, whereas V-shaped options have a fingernail grind that enables bowl turners to work on the outer portions of their creations, allowing them to rough, finish, and add detailed designs, including facegrain work. Recommended sizes for beginners who are working with carbide turning tools for bowls are 1/2-inch and 5/8-inch.

8. Parting tool

Parting tools are used for delivering the final cut in woodworking projects. They also allow for convenient separation when the aim is to swiftly remove scrap material and enhance the appearance of the end results. For beginners, a basic 1/8-inch square nose parting tool is recommended, although there are alternative options available such as fluted, rectangular, and diamond-shaped parting tools.

9. Spindle roughing gouge

The purpose of spindle roughing gouges is to transform square and off-center wooden pieces into smooth-surfaced rounded objects.

A roughing gouge, designed with a wide U-shaped flute to handle heavy-duty tasks, is an excellent tool for shaping wood by tapering it, forming cylinders, and achieving a smooth finish. When working on medium to large pieces of wood, beginner woodturners often find a roughing gouge that measures between 7/8 and 1 inch in size to be particularly suitable.

10. Round nose scraper

Despite its specific name, round nose scrapers have great versatility and can be effectively utilized for both faceplate and spindle turning projects. However, the true strength of round nose scrapers lies in their exceptional ability to effectively smooth and achieve a polished finish on the intricate inner corners of bowls, vases, and other projects with vessel-like shapes.

Scrapers differ from gouges in that larger scrapers are easier to control compared to smaller ones due to the consistent application of surface area, which minimizes the chance of slippage.