The art of shaping wood on a lathe is known as woodturning.

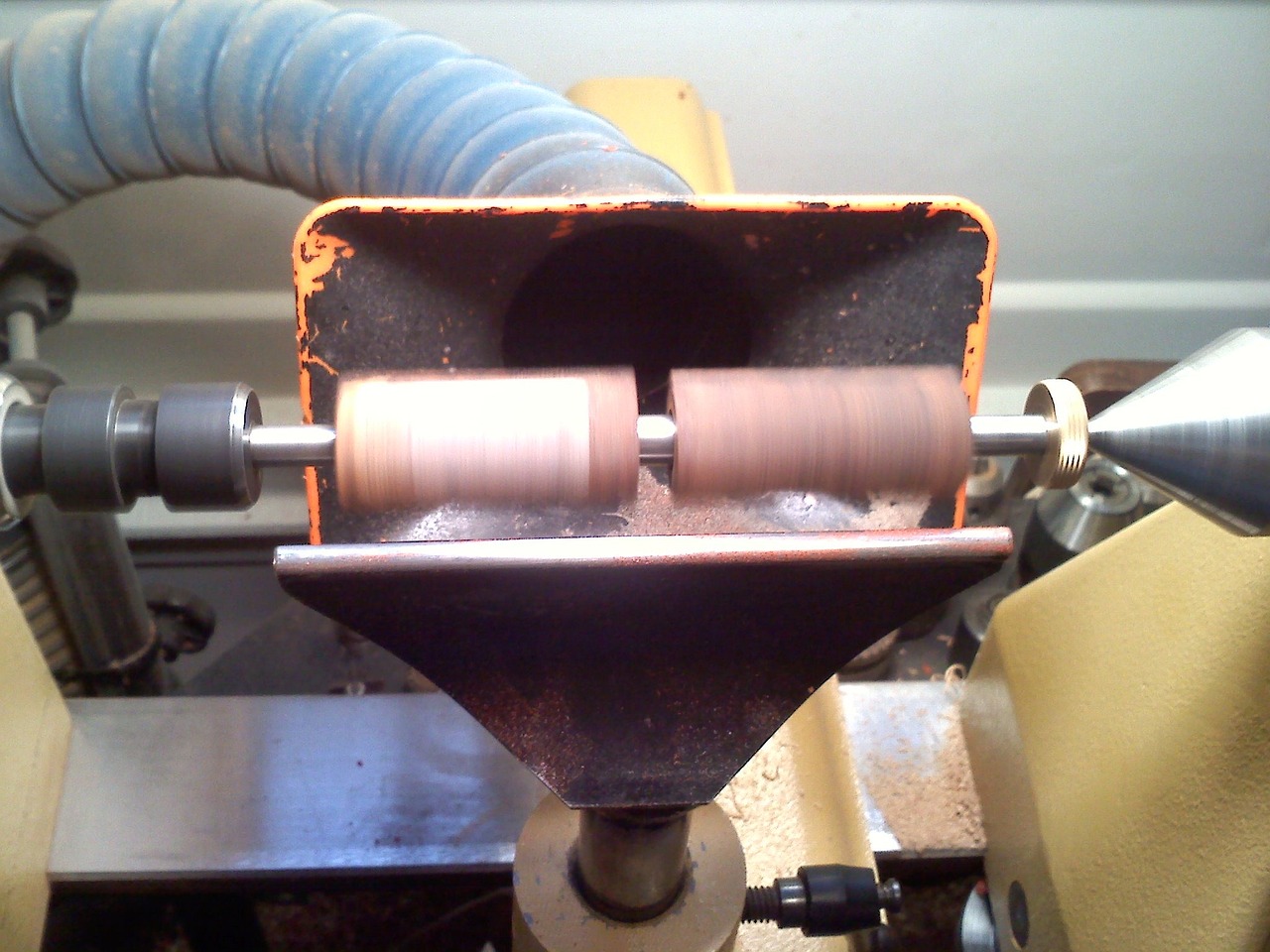

Does the practice involve utilizing a wood lathe along with handheld tools to create a shape that is symmetrical around its rotational axis? Similar to the potter’s wheel, the wood lathe is capable of producing various forms.

Woodworkers who operate the tools are commonly referred to as turners, and the expertise required to manipulate these tools was historically labeled as turnery. During the pre-industrial era in England, these skills were deemed challenging enough to be referred to as “the secrets held by the turners’ guild.” The ability to utilize the tools without a stationary point of contact with the wood distinguishes woodturning and the wood lathe from lathes employed in machining or metalworking.

Products produced using a lathe encompass a wide range of items such as tool handles, candlesticks, egg cups, knobs, lamps, rolling pins, cylindrical boxes, Christmas ornaments, bodkins, knitting needles, needle cases, thimbles, pens, chessmen, spinning tops, furniture components such as legs, spindles, and pegs, architectural elements like balusters and newel posts, sports equipment like baseball bats, hollow objects including woodwind musical instruments, urns, sculptures, as well as everyday items like bowls, platters, and chair seats.

Although industrial production has taken over the manufacturing of numerous products once created by traditional turning shops, the wood lathe remains in use for decentralized production of limited or customized turnings. A proficient turner can create a diverse range of objects using only five or six basic tools. These tools can be conveniently modified to suit the specific task at hand.

Techniques

Surprisingly, complex forms created on a wood lathe stem from a limited range of cuts including parting, planing, bead, cove, and hollowing. Parting is utilized to detach the wood from the holding device or to establish cuts of specific depths. Planing entails using a tool that relies on a bevel below the cutting edge to support the wood fibers, similar to a regular wood planer.

Beads possess a convex form in comparison to the cylinder, while coves exhibit a concave shape. The process of hollowing involves a mix of drilling and scooping to remove material. The woodturner has the freedom to select from a range of tools for these techniques, and the proficiency in handling the chosen tool enhances the quality of the cuts with practice.

When making any type of cut, turners ensure three points of contact: the tool rests on the tool rest, touches the woodturner’s body, and then makes contact with the wood surface, usually with a bevel edge gliding on the wood.

Woodturners aim to place the tool accurately in order for the wood to meet the cutting edge, resulting in a fine shaving without causing any damage or tearing to the wood. The preference of woodturners is to achieve immaculate cuts, minimizing the need for abrasive work.

They use the lathe to sand the piece when needed, either by hand with abrasives or by using an inertial sander that rotates with the wood. Power tools like drills or right-angle drills can also be employed. Additionally, the lathe serves as a convenient tool for tasks such as carving, burning, texturing, coloring, and finalizing the form.

Holding devices

The wood is able to rotate on the lathe by utilizing the headstock, which consists of the drive mechanism, and the tailstock support, which only rotates if it is supported by a rotating holding device. At the headstock end, points or spurs are used to drive into the wood.

The turning method called ‘between centers’ is commonly used. A cup, collet, or scroll chuck can also be utilized by the headstock spindle to secure a tenon on the workpiece that will eventually be eliminated in the final product.

The wood can be affixed to a faceplate or secured with screws or glue. This faceplate is a resilient disk with threading that can be attached to the spindle of the headstock. By utilizing a chuck or faceplate, the woodturner can eliminate the need for tailstock support while the wood is rotating. This dependable method of holding is crucial for hollowing bowls or hollow forms.

This is a brief introduction to getting started with woodturning.

1. You’ll need a lathe

It’s not surprising that a lathe is necessary, but the question is which one to choose. In addition to various brands, lathes are available in different sizes. How can you determine whether a mini, midsize, or monster lathe is the right choice for you?

Your decision will undoubtedly be impacted by your budget and the amount of space in your shop, however, it is also essential to consider the types of projects you wish to create. Are you interested in crafting pens and pizza cutter handles, or larger bowls and sturdy table legs? Do you desire the versatility to turn various items, regardless of their size?

It is crucial to address these questions as they pertain to various essential technical specifications, aiding in the process of narrowing down your search for a lathe.

The distance between centers refers to the measurement between the drive or spur center located on the headstock and the revolving center on the tailstock, at its maximum extension while ensuring safety. This measurement determines the maximum length of the material that can be turned on the lathe.

If you intend to turn table legs that are usually 28″-30″ in length, a mini lathe with an 18″ distance between centers will not suffice as it can only accommodate stock shorter than 18″ in length.

If that’s the scenario, you could either consider a bigger lathe or explore the availability of a bed extension for the mini lathe to expand the distance between centers. However, when it comes to crafting smaller items such as pens, a mini lathe is the ideal size.

The swing over the bed refers to the distance from the lathe bed to the tip of the drive or spur center, which is doubled.

The maximum diameter that can be turned on the lathe is indicated – for instance, a mini lathe with a 10″ swing can handle a blank with a diameter of 10″ (or slightly less) at its widest point. In order to turn large-scale plates or bowls, a larger lathe is necessary, but for small bowls and candy dishes, the mini lathe is suitable.

What is the lathe’s speed range? If you intend to work with large-diameter pieces, it is important to have a lathe that can operate at a slower speed to ensure safety. This is due to the fact that, at a specific rpm, the outer edge of a sizeable blank moves significantly faster than the spindle of the lathe.

Is there a higher risk of vibration and the possibility of detachment if the blank is spinning at excessive speed? Additionally, is the lathe a fixed-speed or variable-speed machine?

Fixed-speed lathes utilize graduated pulleys connected to the motor and spindle, with a drive belt adjustment to achieve a predetermined set of speeds. On the other hand, variable-speed lathes enable a broader range of adjustment within specific speed ranges, offering easier means for making such adjustments.

For mini lathe and smaller turning projects, a 1/2hp motor is sufficient in terms of horsepower. For midsize lathes, the horsepower will vary between 3/4hp and 1-1/2hp, while larger lathes will have a horsepower starting from 1-1/2hp and higher.

After selecting a lathe, it is important to take into consideration two additional factors: the Morse taper of the headstock and tailstock spindles, and the headstock spindle’s size and number of teeth per inch (TPI).

When purchasing accessories like pen mandrels and four-jaw chucks for your lathe, it is crucial to be aware of these technical specifications. Lathes generally come with either a No. 1 or No. 2 Morse taper, abbreviated as MT-1 and MT-2, with MT-2 being the more prevalent option. The usual sizes for the headstock spindle are 3/4″ x 16TPI, 1″ x 8TPI, and 1-1/4″ x 8TPI.

2. You’ll need turning tools

When it comes to turning, the process involves subtracting material to shape and unveil the final form, similar to a sculptor or carver. To achieve the desired design and details, having the appropriate tools is crucial. In the realm of turning, you have the choice between two main categories of tools: traditional turning tools or carbide-insert turning tools.

Turning tools that are traditional

Traditional turning tools have a rich and esteemed heritage, as implied by their name. Craftspeople have relied on these tools for countless years to craft turnings that are both aesthetically pleasing and practical. The contemporary iterations of these tools are typically constructed from tool steel or high-speed steel. It is advisable to opt for high-speed steel (HSS) as it possesses the ability to endure higher temperatures during sharpening without compromising its hardness.

This category includes a brief overview of the most commonly used tools.

There are three main types of gouges: roughing gouges (also called spindle roughing gouges), bowl gouges and spindle gouges (also called detail gouges). The tools’ names hint at the important differences between them.

Spindle gouges and roughing gouges are utilized in spindle turning, which is the process of working with stock that is typically longer than it is wide and is placed in the lathe with its grain direction aligned parallel to the turning axis.

In order to transform square stock into round, roughing gouges are employed, whereas spindle gouges are utilized to craft intricate details such as coves and beads. When engaging in spindle turning, the tool rest of the lathe is usually positioned near the stock, offering support to the tools in close proximity to their cutting edges.

In comparison, when it comes to bowl turning stock, it is typically aligned perpendicular to the lathe’s turning axis, often requiring the tool rest to be placed several inches away. Consequently, bowl gouges are designed with taller walls and deeper flutes to withstand the heightened stress caused by the extended overhang at the tool rest.

The key points to remember are to utilize the tools for their designated functions and, more importantly, to avoid using a roughing gouge on a bowl blank at all costs. Doing so increases the likelihood of it catching, and since it is not designed to withstand the pressure involved in bowl turning, it could potentially shatter and become airborne.

Skew chisels, which feature an angled cutting edge, are employed in spindle turning for creating sleek shearing cuts and shaping V-grooves and beads. These tools come in various sizes and are equipped with flat, oval, or rounded shanks. The angle of the cutting edge can be either straight or curved. It is often necessary for turners to dedicate a considerable amount of practice to become proficient in using the skew chisel.

Parting tools, which come in both rectangular and diamond-shaped shafts, are specifically created to separate a completed spindle turning from the remaining blank. These tools can also be used to create grooves for indicating cutting depths on spindle turnings with different profiles, and thinner versions are also available.

Other tools categorized as specialty tools are scrapers and tools with cutter profiles specifically meant for cutting bead details or shaping the dovetailed recesses needed to secure the bottoms of bowl blanks onto an expandable four-jaw chuck.

3. You’ll need to think about safety

In order to understand the significance of using appropriate safety equipment and adhering to proper practices, it may be beneficial to bear in mind that woodturning primarily entails thrusting a highly sharpened metallic tool into a rapidly rotating wooden piece. It is essential to take necessary measures to prevent any object from getting ejected off the lathe and to ensure personal safety in the event of such an occurrence.

You need at least:

- A face shield – Not just goggles; they can’t stop a chunk of walnut burl from whacking you in the nose.

- Dust collection and respiratory protection – The federal Occupational Safety and Health Administration says wood dust exposure has been linked to allergic skin reactions, respiratory issues and even cancer. And contact with shavings, especially from exotic woods, can cause skin irritation.

- A Turner’s Apron – If you want to protect your clothing and keep shavings from going down your shirt.