Pipe Clamps

Pipe clamps, which are commonly known as pipe clips or saddle clamps, are uncomplicated fittings that are extensively utilized in numerous DIY/installation contexts. These clamps are considered one of the several kinds of channel support systems, frequently observed in plumbing, heating, drainage, and electrical tasks.

When chosen appropriately, pipe clamps can snugly fit around the conduit, cables, or tubing being installed, as they are circular or semicircular brackets that may include a spring clip or ‘bossed’ system.

The clip can attach to the wall or surface, such as wood, tiling, plaster, or masonry, through screws or bolts, either directly or with the help of a hanger bracket. This securely holds and supports the tubing throughout its entire length, guaranteeing a dependable and hassle-free mounting option.

As long as you know what you’re looking for, you should have no difficulty finding pipe clamps of the correct size and style to affix, support, and restrain pipes, tubing, or cables along walls and under ledges. This applies to various scenarios where you might need such clamps.

How do pipe clamps work

We have a basic understanding of their nature, but the functioning of pipe clamps varies depending on the desired task.

Pipe clips and clamps are available in various sizes and diameters.

There are different materials used to make them, including plastic, copper, stainless steel, brass, and chrome. These items come with various bracketing and mounting options, such as single-screw, two-screw, or three-screw, bolt-down, clip-in, and others. Their function is simple: they wrap around tubing or cable and are attached to walls or structures to securely hold conduit in the desired location.

There are two types of pipe clips available: gripping (anchor) and non-gripping (saddle/guide). The choice depends on the desired tightness of the fixed conduit. It is worth considering that in certain situations, allowing some space for movement, such as thermal or mechanical, can be advantageous.

What are pipe clamps used for

Pipe clamps can be found in various household, industrial, and outdoor settings.

Pipe clips are utilized to securely restrain and guide tubing or conduit for various plumbing, heating, and electrical uses in a neat and efficient manner. In the UK, a diverse range of materials, finishes, and styles are available for pipe clips to accommodate tasks ranging from concealing slender cables to providing support for robust wastewater disposal systems.

Pipe clamps for plumbing

Plumbing pipe clamps are commonly used in households and workspaces to neatly and safely secure/support pipeline of different diameters.

In order to correctly choose plumbers clamps, it is important to know the appropriate diameter, grip type, and material for each type of water or drainage pipe. In the following sections of this guide, we will examine the various options available for pipe clips in plumbing applications.

Pipe clamps for drains

Drain pipe clamps, also known as gutter clips or brackets, can consist of fittings to secure wastewater pipes within an indoor plumbing and drainage system. These clamps are also used for fixing UPVC rainwater collection channels to the fascia boards on the outer roof. Although both types of clamps require brackets and clips to support the ductwork, they serve different purposes and are of distinct types.

Just as in central plumbing applications, choosing the appropriate drain pipe clips involves accurately determining the required diameter and shape of the clip to securely secure your wastewater pipework.

Pipe clamps for wood

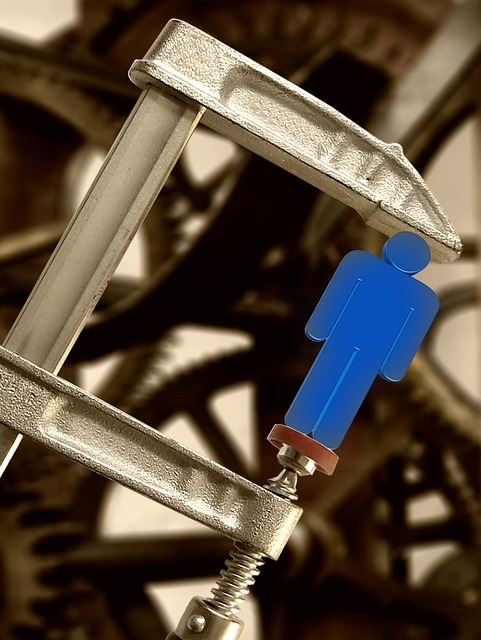

Pipe clamps are often referred to in the context of carpentry or joinery, which can be confusing as their purpose is completely different in this case. In woodworking, a pipe clamp typically refers to a wide, freestanding, and fully adjustable vice clamp that is primarily used to hold several boards together for a stronger join when edge glueing.

Woodworking pipe clamps operate on a similar principle to other pipe clips. It is essential to choose the appropriate diameter, style, and material of clips that can encompass the pipe to ensure a strong grip for securing the end-joints. Otherwise, it will not effectively lock the end-joints in place.

Types of Pipe Clamps

There is a wide range of pipe clamps available, each serving specific purposes and applications. Several commonly used types include:

- C-clamps: These clamps have a C-shaped frame with a threaded screw and swivel pad at one end. They are ideal for holding pipes securely during tasks like cutting or welding.

- Bar clamps: Also known as F-clamps, these clamps consist of a flat bar with a sliding jaw and a threaded screw. They offer a wide clamping range and are useful for securing pipes during assembly or gluing tasks.

- Spring clamps: These clamps have a spring mechanism that allows for quick and easy clamping and release. They are ideal for light-duty tasks and temporary holding of pipes in place.

- Chain clamps: These clamps use a chain to wrap around the pipe and provide even pressure distribution. They are suitable for irregular-shaped pipes or pipes that require rotation during tasks like welding.

- Quick-release clamps: These clamps have a one-handed operation mechanism that allows for quick and easy clamping and release. They are useful for repetitive tasks or when speed is essential.

Materials Used in Pipe Clamps

Pipe clamps can be created using different materials, and each material has its own advantages and disadvantages. Various materials commonly used for making pipe clamps include:

- Steel: Steel clamps offer high strength and durability, making them suitable for heavy-duty applications. They may be susceptible to rust and corrosion if not properly maintained.

- Cast iron: Cast iron clamps provide excellent strength and rigidity but can be brittle and prone to breakage under extreme stress.

- Aluminum: Aluminum clamps are lightweight and resistant to corrosion, making them ideal for outdoor use or in damp environments. However, they may not be as strong as steel or cast iron clamps.

- Plastic: Plastic clamps are lightweight and affordable but may not provide the same level of strength and durability as metal clamps. They are suitable for light-duty applications and temporary holding tasks.

How to Choose the Right Pipe Clamp for Your Project

When choosing a pipe clamp for your project, you should take into account the following factors:

- Type of clamp: Choose a clamp type based on the specific task you need to perform, such as cutting, welding, or assembly.

- Material: Select a clamp material that offers the appropriate strength, durability, and resistance to corrosion for your application.

- Clamping capacity: Ensure the clamp you choose has a clamping capacity suitable for the size of the pipe you are working with.

- Ease of use: Look for clamps with features like quick-release mechanisms or one-handed operation to make your work more efficient and convenient.

- Budget: Consider your budget when selecting a pipe clamp, as prices can vary significantly based on the type, material, and brand.

Proper Use and Maintenance of Pipe Clamps

In order to ensure that your pipe clamps remain durable and efficient, it is essential to adhere to these guidelines.

- Use the right clamp for the job: Always select a clamp designed for the specific task you are performing.

- Do not overtighten: Overtightening a clamp can damage the pipe or cause the clamp to fail. Apply enough pressure to hold the pipe securely without causing damage.

- Inspect clamps regularly: Check your clamps for signs of wear, damage, or corrosion, and replace them as needed.

- Clean and lubricate: Clean your clamps regularly to remove dirt and debris, and apply a light coating of oil to metal parts to prevent rust and corrosion.

- Store properly: Store your clamps in a dry, cool area when not in use to prolong their lifespan.

Safety Tips When Using Pipe Clamps

To avoid potential risks, it is important to follow these safety tips when working with pipe clamps.

- Wear appropriate personal protective equipment (PPE): Wear safety glasses, gloves, and other PPE as necessary when working with pipes and clamps.

- Secure the work area: Ensure your work area is free of tripping hazards and that the pipe is securely clamped before beginning any tasks.

- Do not use damaged clamps: Inspect your clamps before use and avoid using any that show signs of damage or wear.

- Follow manufacturer guidelines: Always follow the manufacturer’s instructions and recommendations for using and maintaining your pipe clamps.