Woodwork encompasses both art and science, emphasizing subtlety. Minor errors in woodworking can be a drain on your time, finances, and potential future projects. However, with a bit of prior knowledge, you can steer clear of numerous common and easily preventable woodworking blunders. Here, we present a compilation of the most widespread mistakes in woodworking.

The router is burned.

By enabling you to hollow out wood, create designs, form shapes, and make cutouts, routers allow you to incorporate intricate and artistic touches into your work, giving it a distinct and personalized signature. Adding professional-level detail to your projects becomes possible with their assistance.

They can also be used in joint creation due to their ability to create smooth surfaces on accurately sized joints, resulting in strong bonds.

Regrettably, router burn can occur due to the routers themselves. The friction generated by the routers results in heat, which can result in unpleasant burn marks on the wood. The higher the router’s speed in revolutions per minute (RPMs), the more likely router burn becomes.

To prevent router burn, ensure that the router is clean and sharpened prior to use. Increased friction arises from dirt, dust, resin, and a lack of sharpness, which consequently accelerates the router’s attainment of burning heat.

To prevent router burn, one alternative is to use it in a controlled manner. When attempting to create a deep inlay, it is advisable to operate the router at a slow pace, making several shallow passes instead of attempting a single deep pass.

If the router is clean, you are still more likely to leave router burn if you run it for a longer time without giving it a chance to cool down. It is also advisable to decrease the router speed, especially for species that are prone to router burn.

2. Issues with moisture levels.

The moisture content of wood is always influenced by the temperature and relative humidity of the surrounding air, as wood continually absorbs and releases moisture. While finishes such as stain or paint can restrict the movement of moisture between the air and wood, they cannot completely eliminate it.

In a dry setting, the wood’s moisture will evaporate into the air that has less moisture, which may lead to shrinkage and cracking of the boards. This, in turn, can result in gaps forming at the joints. Conversely, if there is a high level of humidity in the air, the wood will absorb the excess moisture.

When the wood swells, it can result in either buckling or splitting, which leads to deformities and poor fits in drawers, cabinets, and door frames. Even tables and other non-framed items can develop separations and cracks, ultimately damaging the overall aesthetic appeal of your piece.

One error frequently made by woodworkers during the process of acclimating the wood, aside from disregarding the acclimation process altogether, is assuming the wood is ready without any basis. It is important not to assume that the wood has acclimated simply because a specific duration of time has elapsed. The only way to accurately determine if the wood has achieved a suitable moisture level is by utilizing a moisture meter to measure its moisture content.

Using a blade that is dull or incorrect

Do not make bad saw blade choices, as these two mistakes, although separate, ultimately result in the same issue.

To begin, if you were to use a dull razor, you wouldn’t shave. So, why would you utilize a dull blade for your woodwork? It will not result in a clean cut. Consequently, you will either have to perform additional manual work to rectify it or end up with a misaligned piece that spoils your building project.

When blades are dull, they face significant resistance which leads to increased friction. Just like with a dirty or dull router, this friction and resistance can result in burn marks on the wood.

It is important to note that dull blades pose a safety risk as well. In order to cut through the wood, more force is required, which in turn can lead to the wood splitting, the blade breaking, or mishandling the saw in a dangerous manner. Therefore, it is advisable to inspect the blade before using it. In the event that it is not sharp, you should consider sharpening it if possible, seeking professional assistance for blade sharpening, or purchasing a new blade.

If you choose the incorrect blade or saw, you will encounter difficulties. Take into account the materials, their intended purpose, and the type of cut required when deciding on the appropriate saw and blade. It is not advisable to utilize a framing blade for precise cuts. The greater the number of teeth on the blade, the more refined the cut will be. If you are uncertain about which blade is suitable for the task, seek advice from an expert or conduct some research.

The fourth step is called a blowout (or tear out).

One more unsightly outcome of utilizing a blunt or incorrect blade is blowout, otherwise known as “tear out.” Blowout refers to the fragments or pieces of wood that are forcefully extracted when employing various tools. It results in uneven or damaged wood, which is an undesirable outcome. This occurrence should be avoided.

Blowout is more likely to occur when the route crosses the grain, as this is where the grain’s support structure is at its weakest. This is the reason why blowout frequently happens when transitioning the router from end grain to edge grain in order to create a smooth curve.

Blowout can happen when you push the tool too fast. The likelihood of blowout increases as the speed of pushing a router increases. Using clean and sharp tools and carefully considering the cutting direction reduces the chances of blowout occurring.

Extra caution should be exercised for certain species, like cedar and oak, as they are more prone to splintering compared to other species.

5. Buying cheap tools

As we walk through the aisles of large retail stores, we often gaze at discounted prices in search of the greatest bargains. However, the greatest bargain does not solely rely on the displayed cost of a tool. The most suitable tools for your woodworking endeavors are those equipped with the necessary features for both current and upcoming projects.

If your projects will differ in size and material, it is advisable to consider using a compound sliding miter saw. This type of saw enables you to make 12-inch cuts in plywood, which cannot be achieved with a regular miter saw. It is common for some woodworkers to initially opt for a cheaper saw, only to realize that the cutting capacity falls short of their requirements.

Instead of starting with a benchtop table saw that has a limited capacity for cutting larger plywood or hardwoods, opt for a contractor saw that you won’t have to replace. When it comes to tools, it’s wise to adhere to the saying, “Buy once, cry once.”

6. Using the wrong wood joinery

Woodworking appears easy until you encounter your initial projects that necessitate consideration of how two pieces of wood will be joined. Regrettably, this implies that not all wood joints can be secured using the commonly relied upon pocket hole screw, which occupies a prominent position in the workshops of numerous DIY enthusiasts.

When constructing a cabinet box, it is advisable to employ nails and glue if the end product is visible. However, for face frames, either a biscuit or pocket hole can be used satisfactorily as they are not visible.

Although it is widely recognized that a dovetailed drawer is the most robust and long-lasting option, many novice woodworkers might not possess the necessary resources such as $400 worth of jigs and routers to create them. In such cases, a half lap joint or pocket holes (preferably with hidden heads) can serve adequately for typical drawer necessities.

If you find that you rely heavily on one woodworking joint for your projects, consider expanding your skills by incorporating other techniques such as using biscuits, mortise and tenons, dovetails, or even the renowned Festool Domino.

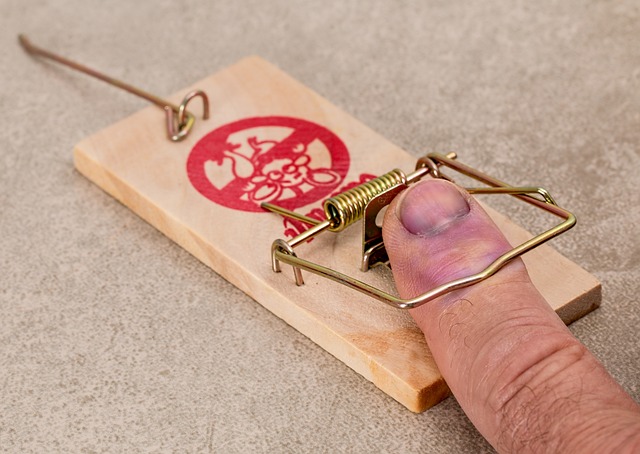

7. Bypassing safety features

Many woodworkers begin their work by removing the riving knife and shield from their table saws without realizing that table saws cause over ten amputations per day in the USA alone. This means that the chances of having an accident are significantly high when using a table saw for ten years.

Instead of taking the risk of injuring your fingers, eyes, or any other body parts, follow these steps instead.

- Follow the manufacturer safety instructions of every tool

- Use safety glasses

- Leave protective blade guards in place

- Choose safety push sticks over fingers

- Hand tools like routers and circular saws must have blades and bits stopped before setting down

- Think long term and invest in lung health too with dust management solutions and respirators

If the feeling is not right, it is best not to make cuts that are not considered safe, even though there is limited guidance on this matter.

8. Not managing dust

Many woodworking enthusiasts and even professionals often overlook the simple but crucial task of managing the dust in their workshop. Thankfully, there are three easy solutions to address this issue.

- Use a dust collector for your table saws, router tables, and jointers. These machines will collect a high volume of dust.

- Second, dust extractors connect to miter saws, random orbit sanders, and other small tools to pull finer-grained dust into a filter and keep it out of the air.

- Lastly, and not commonly used, a power dust filter system will cycle air and capture small micron dust that hangs in the air for an hour after your saws and sanders stop.

Although the presence of some dust doesn’t bother most woodworkers, cleaning the woodshop floor is time-consuming and poses a health risk.

9. Improper panel preparation and glue-ups

The heart of nearly every woodworking project involves a glued panel, of which the shape and size may vary. This implies the need to select dried wood, cut it into an appropriate width (a general guideline being no wider than 3-1/2 inches), and accurately straighten the edges.

What potential issues can arise? Well, numerous woodworkers are prone to committing one or more of the subsequent errors:

- Starting with wood that is twisted and won’t make a flat panel

- Not using a jointer to straighten the edges of the wood

- Using wood wider than 4-inches

- Picking clamps with insufficient power (pros use bar clamps as they are cheap)

- Over-clamping the wood panel and squeezing all the glue out to create a dry joint

- Lastly, not allowing at least 24 hours for the panel to dry before sanding or planing

Although there are numerous other potential errors that could occur, these mistakes mentioned are frequently made and can be easily avoided.